Best Replica Watches Info

Movement Polishing, Craftsmanship, And The Twelve Rules Of Geneva, The Best Rolex Replicas

In 2021, Rolex’s turnover will be 54.837 billion, and a total of 1.05 million watches will be sold, accounting for 28.80% of the world’s watch share.

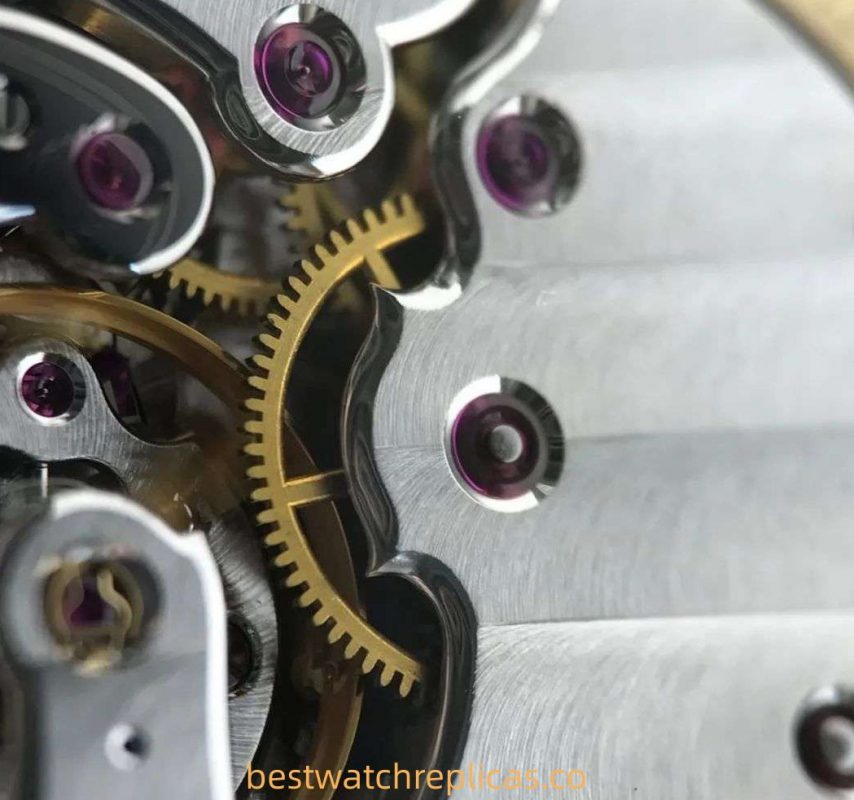

In high-end mechanical watches (such as Lange PP Philippe Dover), the core purpose of polishing the movement is not to pursue the specific roughness of the surface but the beauty and delicacy under the perspective of the back; based on this, we judge the machine When grinding the core, it is also necessary to consider the grinding under the back cover and even under the plywood.

- High-end watch polishing

Three main polishing methods for high-end watches are Geneva stripes, fish scale & pearl patterns, and chamfering. A typical combination of sanding is to use Geneva stripes (parallel grains, others like Omega have radial waves) on the plywood. Best Rolex replicas.

Hang chamfers on independent blocks.

Under the plywood, use a fish scale pattern & pearl pattern to pave a large area.

In this combination, more refined brands, such as Lange, will use different polishing methods on two intersecting parts:

Small independent watchmaking brands such as Philip Duffer will also grind extremely sharp chamfers (mass-produced machines cannot do it):

Geneva stripe + fish scale pattern & pearl pattern + chamfering is a commonly used polishing method for high-end watches, especially watches that have passed the assessment of the [Geneva Twelve Guidelines] and bear the Geneva mark. It’s a pity that this kind of watch is rare in the entire market, and the shipment volume is less than one percent of Swiss watches. Those who can play to this level can be called senior cousins.

Rolex rarely has a back watch and will have a primary polishing method.

The oscillating weight uses radial Geneva stripes, and the bottom splint uses fish scale patterns.

Some watches use sandblasting during the process of polishing the movement.

TAG Heuer Caliber 02 Chronograph Movement (Lower Plywood)

Here again, it involves the difference between sandblasting and frosting.

Sandblasting in the industrial field is expected in spraying quartz sand and glass sand on the surface of stainless steel. After spraying, the character will form an off-white surface, which can be regarded as a finished product in production; the sandblasting material for watches is not clear to me personally, but The final effect of sandblasting goes beyond aesthetics.

But unfortunately, for some brands with a more affordable price, back through often does not use a highly complex combination of polishing methods (processing costs), and even more unfortunately, the first mechanical watch of young watch friends may not have back through, such as Tissot, Mido, Longines essential three needles, and even domestic old Shanghai watches and quartz watches, it is a bit difficult to discuss the Geneva stripes at this time. Richard mille replica.

- Polishing

The ultimate goal of polishing is to obtain a smooth and bright surface, such as the standard steel ball polishing in the industrial field. After rough polishing of steel balls, lime, and abrasives in an inclined drum and then supplemented by fine polishing of fur fragments, a smoother surface can be obtained in the end. Bright surface.

The polishing in life is typical when we go to the 4S shop for maintenance. The maintenance brother uses a large-caliber polishing wheel to polish the casing and smooth scratches, which can restore the car’s original color.

However, in watch maintenance, it is rare for a master to restore the smoothness of the surface of the movement through polishing.

On the one hand, this will seriously affect the accuracy of the movement time, which runs counter to the purpose of maintenance; on the other hand, the movement is difficult to be scratched by the outside due to its airtightness.

More importantly, polishing is at the expense of some materials, which is undoubtedly worse for already “very thin” moving parts.

If you want to smooth a pit, you must file all the surfaces near the hole, meaning the original “normal thickness” parts are ground to a thinner thickness.

If you are wearing this Bulgari octo ultra-thin model, with a thickness of 1.87 mm, the movement is the case, and it may be “disappeared after grinding the watch.”

The movement does not need to be ground, and scratches and bumps on the case are inevitable. If the warranty card expires, how to prevent “wearing the watch”?

- Steel repair

When it comes to this, “steel supplementation” will be involved.

Simple polishing will make it “thinner and thinner.” If a hard object hits our watch, there will be a large crack or gap not in the warranty period.

A conscientious watchmaker will replenish steel for our watch case under the premise of “fair price,” that is, fill the watch case’s gaps with melted steel and minimize the loss of raw materials.

Laser welding, laser welding is a revolutionary repair technology. (This will cost extra)

Filling up the pit and then grinding it flat, the principal loss is the restoration material.

After the steel is repaired, the steel overflowing from the gap can be polished to restore the watch case as healthily as possible and reduce the loss of parts during grinding.

This point also involves the issue of after-sales maintenance. The street shop and the official maintenance service center may have the same effect, but the process and details may differ. The differences here are mainly in the steel case and movement: oiling and splint maintenance.

Within the budget, choosing the official service center first is recommended. The most important reason here is the nature of material loss and labor costs, as well as the differences in the working methods of maintenance teachers.

As precision machinery, even entry-level mechanical watches do not use large-diameter polishing wheels standard in the automotive industry during the grinding of the case and the production of movement parts. The careful polishing of high-end movements is more engraved in the “Geneva Twelve Guidelines.”

- The Twelve Rules of Geneva

Switzerland is a federal country. The Twelve Rules of Geneva were established in 1886. At that time, watches from various regions of Switzerland flowed into the Geneva area, which had a significant impact on the local watchmaking industry; to protect the local watchmaking industry, the provincial government Formulated the Twelve Rules of Geneva, the essence of which is to avoid lousy competition from the outside world.

This set of rules stems from two primary conditions: the watch must be produced by a local watch factory in Geneva, and the producer must meet 12 basic rules in terms of movement processing (the Geneva Twelve Guidelines are quoted from WatchAdmin):

First Rule:

(1A) All parts in the movement, including the added mechanical devices, must meet the strict requirements of Rule 12 and be subject to sampling inspection. It means that the surface of all parts made of metal materials and additional mechanical devices must be flat, the edges must be chamfered and polished, and all parts’ inner and side surfaces must be ground.

(1B) The edges of all steel parts must be chamfered, ground, and polished to a mirror finish. The advantages and notches of all screw caps must be chamfered and polished, and the screw tails must be flat or spherically polished.

Second Rule:

Except for the mainspring box, the mainspring axis, and the axis hole of the center wheel of the bottom plate, which do not need to be equipped with rubies, all other movement wheel trains, escapements, horses, and balance wheels must be fitted with ruby bearings. The holes must be highly polished; the plane in contact with the gear must be polished in an arc, or at least plane polished, to reduce the friction area. The center hole of the ruby must have a bell-shaped oil storage tank, and it must be highly polished to prevent the oil from spreading and losing, while the periphery of the ruby must be concave and polished for beautification. It is better for the escape wheel and the horse to have supporting stones like the balance wheel to minimize the friction force; at least, the escape wheel should have upper and lower supporting stones.

The third Rule:

The hairspring must use a Breguet-style double-layer blue steel hairspring, and a single-layer blue steel hairspring for ultra-thin movements is also acceptable. The hairspring head on the balance wheel must be locked and fixed by a single charge with a round neck; a free-sliding movable metal pressure plate or an adjustable supporting screw bolt is also acceptable.

Fourth Law:

The hairspring adjuster, that is, the speed indicator needle, must have a fixed device and can be fine-tuned (such as a gooseneck fine-tuner), and the ultra-thin movement does not need a machine for fine-tuning the speed needle. If there is no speed needle design, there must be a compensation screw on the balance wheel to fine-tune the speed. At least two or four new beryllium-nickel alloy enamel code compensation balance wheels, or at least 4 or 8, can fine-tune the pace without compensation. The circular optical pendulum of the screw is acceptable in modern times.

Rule 5: Mechanisms and parts such as the oscillating plate that drives the balance wheel to rotate, the structure that adjusts the isochronous beat, and the speed and slow hands must meet the requirements of Rules 1A and 1B.

Sixth Rule: The gear train’s transmission ring edges and support beams must be chamfered, and the joints with the small teeth must be polished and modified. For gears with a thickness equal to or less than 0.15 mm, only one side can be chamfered, and the ground and the drive ring can be ground. If the gear thickness is more significant than 0.15 mm, both sides of the gear must be chamfered and base.

Seventh Rule: All gear train steel teeth and their cross-sections, axle ends, and stems are to be mirror polished. That is to say, all the gears of the transmission gear train must be ground and cut corners, and the steel teeth, including all parts, must be mirror-polished to make them dazzling, and the oil will not be diffused and lost due to capillary phenomena. When both the ruby and the shaft are mirror-polished, the frictional resistance will be reduced, and the lubricating oil will also condense into a spherical shape due to the physical effect of cohesion so that the oil will not be diffused and lost due to the capillary phenomenon due to the rough surface.

Eighth Law:

In the structure of the escapement system, the escape wheel must be light, and the horse should preferably have a balance device. For movements larger than 18 mm, the thickness of the escape wheel should preferably not exceed 0.16 mm, and for activities smaller than 18 mm, the thickness of the escape wheel should not exceed 0.13 mm. The friction surface of the balance wheel and the ruby should ideally be between 0.07 mm and 0.03 mm. The smaller the friction area, the less the loss of kinetic energy and the best effect of energy release. Of course, only the best steel can achieve high efficiency—long best condition.

Ninth Law:

In the structure of the lever escapement system, the horse swings left and right to release energy while driving the balance wheel to run; the positioning mechanism to stop the horse must be limited by a static splint, whether it is on the main board or the horse board, it is acceptable, but Parts that can move or change positions at will are not allowed. Among them, there is a positioning restriction structure inlaid with two rubies as horses, which is the most advanced, and using stud-type fine-tuning eccentric bolts is prohibited.

Tenth law:

All movements must be fitted with anti-shock devices. Pocket watches around 1900 and many activities from 1940 to 1970 were stamped with the Geneva mark. Watches like Patek Philippe and Vacheron Constantin were not equipped with shock absorbers then so this Rule may have been added after 1970.

Eleventh Rule:

The special regulations of the registered model must manufacture the ratchet and crown wheel in the winding system structure. The engagement of drum carts, auspicious carts, small steel wheels, and large steel wheels must be polished to make it easy to wind up the chain. To achieve the purpose of sturdiness and durability, the small steel wheels must be vertically double-layered, and the large and small steel wheels should preferably have a wolf tooth shape. This can be seen in antique high-end clocks and watches. Most of the recent representatives are only chamfered and polished—tooth type.

Twelfth Law:

Springs bent from wire cannot be used. There are gears with spring performance in the movement, such as clockwork gears or drums, clutch springs, calendars and automatic gear trains, minute repeaters, timekeeping, clocks, and perpetual calendars. The springs used in their parts must be cut, carved from the steel plate, and polished to make parts with elasticity and beautiful lines. No matter whether any component is operating, it must be returned with the help of a spring. Even if the shape of the spring is as thin as paper, whether long or short, it must be fixed by a positioning nail. It cannot be bent and formed with the current or flat spring or replaced with a spring without screws.

The Twelve Rules of Geneva have been the highest standard of watchmaking technology for a long time.

Before 2008, only Patek Philippe, Vacheron Constantin, Roger Dubuis, Chopard, and Gero Zunda were awarded the Geneva Seal. Until a tourbillon from Cartier was stamped in 2008, Patek Philippe had been a reasonably solid Geneva Seal. Defender (Patek Philippe and changed to PP imprint in 2009).

Looking back at present, the Geneva Code has its limitations and unfairness; At the same time, the world admires the Geneva Seal so much its symbolic meaning has conflicted with its local self-preservation.

After all, even a Swiss watch factory that is skilled in technology but originated from other regions cannot meet the standard of the former [Geneva manufacturer].

The change of the Twelve Rules of Geneva to “advance with the times” is more due to the original intention of the Geneva government to protect local enterprises.

However, overlapping multiple standards guarantees the quality of local watchmaking in Geneva, regulates the industry status quo of counterfeit and shoddy products, good and evil, and plays a vital role in the reputation of local Swiss watch exports to the world.

This means watchmaking companies from Lake Geneva to the south of the Jura Mountains have a more relaxed environment for researching technology and polishing processes rather than running around for profits. This kind of watchmaking is conducive to “focusing on creation and innovation” The environment has played an epoch-making forward-looking role in the reputation of Swiss watch exports to the world.

Gender: Men’s

Brand: Rolex

Case Size: 40mm

Band Length: 19cm

Engine: Rolex Calibre 7750/Mingzhu Engine

Case Thickness: 16mm

Model: 116506IBLDO

Series: Daytona